At first glance, the newly released M4 MacBook Air shares a striking resemblance with its predecessor. Apple has opted to retain the same elegant chassis that was first introduced with the M2 MacBook Air, signaling that the company is confident in this well-received design. But beyond its external appearance, how much of the internal structure remains unchanged?

One of the most reassuring aspects of this continuity is that many repair and upgrade procedures follow familiar steps. For consumers and repair professionals who have experience with the M2 and M3 models, servicing the M4 MacBook Air won’t present any drastic changes or unexpected challenges.

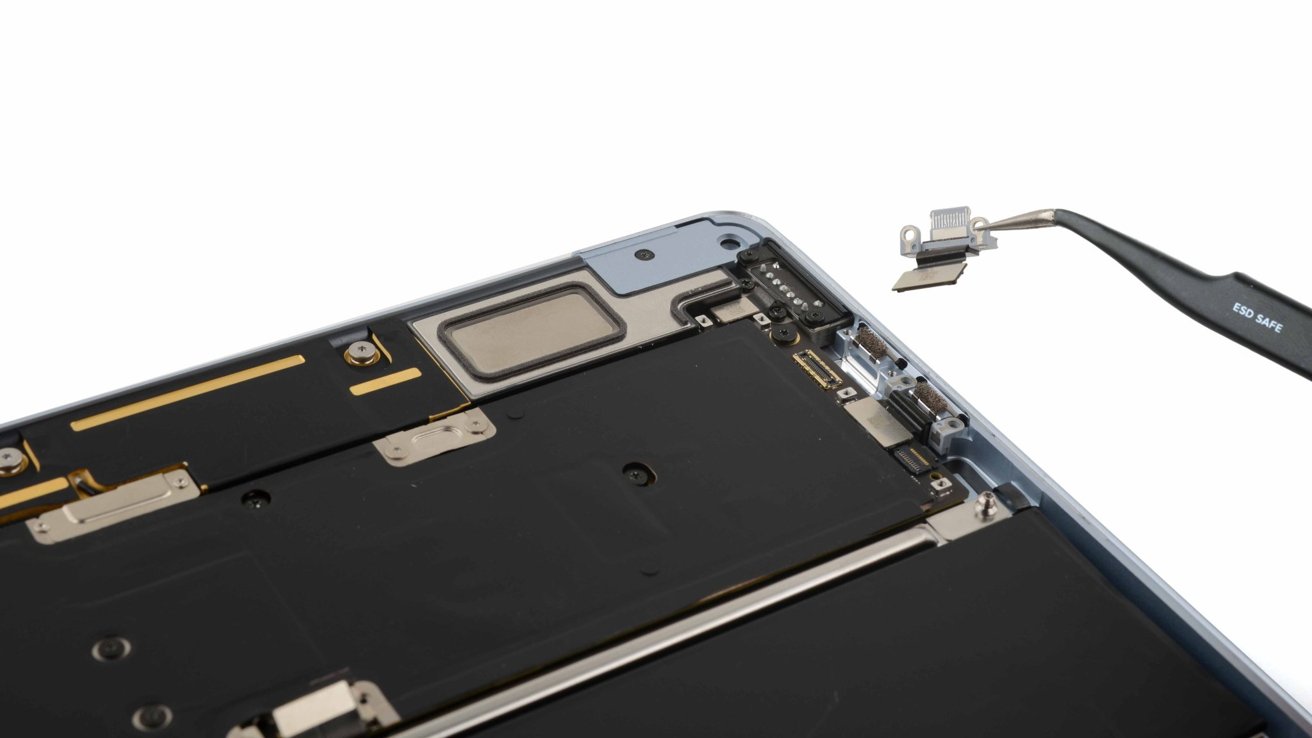

- USB-C Port Replacement: Just like in previous models, the USB-C ports in the M4 MacBook Air are modular, making them relatively easy to replace compared to other components. This is a noteworthy advantage, as USB-C ports experience frequent wear and tear over time.

- Battery Design: Apple has retained the same stretch-release adhesive pull tabs for securing the battery. This makes battery replacements far more manageable than models from years past, where battery removal required heating and prying through excessive amounts of glue.

- Logic Board and Components: The internal layout of the logic board and primary components remains virtually identical. While this is beneficial for repair consistency, it also means that upgradeability remains as limited as before—most notably, the NAND flash storage remains soldered directly to the logic board, preventing user upgrades.

- Keyboard and Touch ID: A downside that persists is the complexity of replacing the keyboard and Touch ID power button. Accessing these components requires removing nearly the entire top case, making repairs of these parts difficult and costly.

While Apple’s choice to keep the overall design unchanged may disappoint those hoping for breakthroughs in modularity and accessibility, there is a silver lining: the lack of significant redesigns means that parts, tools, and repair knowledge from previous models remain widely applicable. Given Apple’s history of introducing major design overhauls every few years, it’s not surprising that the company has decided to stick with a successful formula—for now.

However, even with these familiar design elements, repairing the M4 MacBook Air still presents its share of challenges. While some components remain modular and relatively easy to replace, others continue to be difficult or outright impossible for DIY repair enthusiasts, leaving consumers dependent on Apple’s official repair services or certified technicians.

One of the biggest obstacles to repairability remains the heavy reliance on proprietary calibration tools and software locks. As noted during iFixit’s teardown, swapping key components—such as logic boards—between identical M4 MacBook Airs resulted in unexpected calibration issues. Even though Apple’s official repair manuals outline replacement procedures, real-world attempts to swap out hardware can still be met with frustrating software roadblocks. For example, after replacing the logic board, iFixit was unable to restore full functionality of the ambient light sensor, even after using Apple’s proprietary System Calibration tool. This meant that True Tone, Apple’s color temperature adjustment feature, could not be re-enabled, highlighting the continued challenges posed by Apple’s strict hardware-software integration.

Another common frustration is the difficulty of removing certain components due to Apple’s use of adhesives. While the battery pull tabs make battery removal more straightforward in comparison to some past MacBook models, other parts—such as the trackpad and speakers—remain glued in place, requiring extra care to avoid damage. Display replacements, though possible, continue to be a tricky process that involves delicate ribbon cables and careful handling of fragile components.

Apple’s staunch approach to memory and storage configuration also limits repair and upgrade possibilities. Just as with previous models, the NAND flash chips remain soldered directly onto the logic board, preventing any aftermarket storage upgrades. This means that users must carefully choose their preferred storage option at the time of purchase, as there is no way to add more capacity later—a disappointment for those who prefer a more flexible upgrade path.

Additionally, while Apple has made strides in offering self-service repair options, the practical feasibility of such repairs remains a challenge. Even with Apple’s official self-repair program, consumers must navigate a complex system of part serialization and software pairing to ensure full functionality of replaced components. This complexity can deter many users from attempting repairs on their own, leading them to rely on Apple’s costly in-house repair solutions.

Despite these challenges, there are still aspects of the M4 MacBook Air that make repairs less daunting than in previous MacBook generations. Easily removable USB-C ports are a particular win for repairability, as these ports undergo significant wear over time and often require replacement. The retained modularity of the display and battery—albeit with some adhesive complexities—also provides a measure of relief to repair advocates. However, Apple’s continued decision to integrate critical components in ways that limit repair and upgrade options suggests that, while progress has been made, there is still a long way to go in making MacBooks truly repair-friendly.

For those hoping that Apple might have taken significant steps forward in improving the repairability of the MacBook Air lineup, the teardown of the M4 model confirms a reality that’s all too familiar. While the laptop maintains several modular components that aid in repairs, other design choices continue to pose roadblocks. The findings highlight a mix of both welcome conveniences and ongoing frustrations.

One of the more positive aspects of the teardown is the ease of replacing USB-C ports. These ports are still modular, meaning they’re not soldered directly onto the logic board—a design aspect that simplifies repairs considerably. Given that USB-C ports are prone to wear and tear over time due to frequent cable insertions and removals, making them user-replaceable is a relief for both professionals and DIY repair enthusiasts. The battery also remains relatively serviceable, using the same stretch-release adhesive pull tabs seen in recent models. This method, while not as effortless as a simple screw-based attachment, still allows for much easier removal compared to older MacBooks that relied on stubborn adhesive layers.

However, there are still notable pain points. Swapping out certain hardware components, such as the logic board, continues to be problematic, largely due to Apple’s calibration restrictions. During iFixit’s teardown, replacing the logic board between two identical M4 MacBook Air units resulted in unexpected calibration issues, particularly with the ambient light sensor. Even after running Apple’s proprietary System Calibration tool, the display’s True Tone functionality remained disabled. This highlights Apple’s continued reliance on software locks, which can prevent even legitimate repairs from restoring full functionality.

Another significant drawback is the integration of NAND flash storage onto the logic board. Just as with previous models, the storage in the M4 MacBook Air is not upgradeable, meaning that whatever capacity a user selects at purchase is what they’ll be locked into for the life of the device. This limitation has long been a grievance among repair advocates and tech enthusiasts, as it forces consumers to pay a premium upfront for additional storage rather than giving them the flexibility to upgrade later.

The teardown also reveals that certain components, such as the Touch ID power button and keyboard, remain extremely difficult to replace. These parts are deeply integrated into the MacBook’s top case, making repairs not only time-consuming but also costly. If the Touch ID sensor fails, for instance, users can’t simply swap it out—it requires replacing nearly the entire top case assembly, which significantly increases repair costs.

Apple’s use of adhesives also continues to be a mixed bag. While some areas, like the battery, utilize more repair-friendly solutions, other areas still rely heavily on glued-in components. This makes repairs for elements like the trackpad and speakers more challenging, requiring additional effort and risk to remove them without causing damage.

While the M4 MacBook Air’s repairability remains consistent with previous models, and in some ways marginally improved, the overall approach still favors controlled, authorized repairs rather than empowering users with true repair freedom. The good news is that owners of the M4 MacBook Air won’t find themselves facing dramatically more frustrating repairs than those with an M3 or M2 model. The bad news? It’s still far from an ideal, fully repairable design.

For consumers who care about repairability, the M4 MacBook Air’s teardown delivers mixed news—some positive advancements, but also a continuation of long-standing challenges. Apple’s decision to retain much of the internal design from previous models means that certain components remain modular and somewhat serviceable, but the company is still doubling down on practices that limit true upgradeability and independent repair.

One of the biggest implications of this teardown is its impact on the ongoing Right to Repair movement. While Apple has made some progress in providing official repair manuals and expanding its Self Service Repair program, the reality is that many essential parts—such as the logic board and Touch ID sensor—are still difficult or nearly impossible to replace without Apple’s authorization. Proprietary software calibration requirements mean that even skilled repair technicians or DIY users may struggle to fully restore device functionality after a repair. This effectively discourages third-party repairs and keeps consumers locked into Apple’s official repair ecosystem, where costs are often significantly higher.

Storage limitations are another critical factor for consumers to consider. Since the NAND chips remain soldered onto the logic board, users must decide at the time of purchase how much storage they’ll need for the lifetime of their device. Unlike other laptops that allow for post-purchase SSD upgrades, Apple’s approach removes this flexibility entirely. This means consumers who underestimate their storage needs may find themselves forced to buy a brand-new laptop sooner than expected, rather than simply upgrading their current one.

Battery longevity and replacement costs are also key concerns. While the stretch-release adhesive pull tabs make battery replacement easier than in some older MacBook models, Apple’s battery pricing structure could still deter consumers from opting for official repairs. Given that batteries degrade naturally over time, users will likely face a situation where they need a battery replacement after a few years. If repair costs remain high, many users may feel pressured to upgrade to a new device instead, even if the rest of their MacBook Air is functioning perfectly.

For independent repair shops, the M4 MacBook Air presents a familiar challenge. Thanks to the largely unchanged design, repair technicians experienced with the M2 and M3 models will find themselves navigating familiar terrain. That’s a positive, as it means existing knowledge, tools, and techniques remain applicable. However, the hurdles presented by software restrictions, serialized components, and Apple’s rigid repair ecosystem continue to make independent repairs more difficult than they should be.

Ultimately, for the average consumer, the reality of MacBook Air repairs remains largely the same. If the device suffers a minor failure—like a worn-out USB-C port or battery degradation—there are reasonable repair paths available. But for more catastrophic failures, such as a logic board issue, the high cost and complexity of repairs may lead many consumers toward replacing the device entirely. This raises important questions about the environmental sustainability of Apple’s approach, as difficult-to-repair devices contribute to increased electronic waste.

While the M4 MacBook Air doesn’t introduce new obstacles to repairability, it also doesn’t remove many of the existing ones. As Apple positions itself as a company committed to sustainability, repairability must become a greater priority. Until then, consumers and repair advocates are left with a device that is serviceable in some areas but remains frustratingly restrictive in others.